Super drill is able to control six axes, rotary table A. B axes is available , Automatic tools changer 16 tools or 32 tools[Option], Automatic Guides changer 10 guides[Option].

1. Chinese and English display. Japanese, Germany, and French languages are available with optional fonts.

2. Optional metric and imperial unit of measure.

3. Mechanical, working, and relative coordinates display.

4. Three manual modes of continuous, step, and protection free.

5. Mechanical homing and centering function.

6. Auto finding edge, center of two points, center of circle, and vertex of right angle and coordinates rotation and mirroring functions.

7. Genuine G/M code editing with workpiece program capacity up to 10,000 nodes.

8. DXF and linear cutting machining program file conversion function.

9. Dialog based program editing function.

10. Square and circular array special module organization program editing function.

11. Machining subroutine calling function (up to 8 layers of subroutines).

12. Multiple machining condition libraries. Each library can hold up to 100 operator machining conditions.

13. Storage for up to 100 operator machining depths.

14. Single and multi hole machining.

15. Program setup (beginning and ending line number setup).

16. Electrode auto detection for machining depth and return to preset height for machining surface when given depth is reached.

17. Auto total machining depth compensation after electrode replacement in case the electrode is used up during single- and multi-holes positioning machining.

18. Variable thickness machining.

19. Back gap and pitch error compensation function.

20. Auto electrode replacement with ATC (auto electrode replacement) assembly (requires special accompanying hardware accessory).

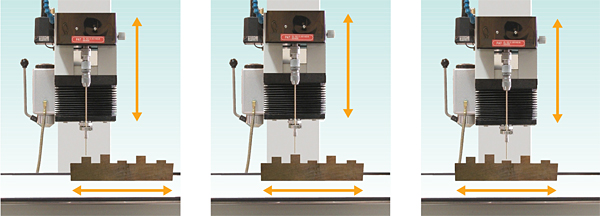

21. 6 axes linear interpolation and acceleration and deceleration motion (requires special accessory).

22. Auto error diagnosis function.

23. I/O points, C points, S points, A points, timer and counter status.

24. 15" LCD panel with touch control.

25. Online help.

26. Programmed simulation function.

27. Machining path display.

28. Software limit function.

OPTIONS:

Z2 axis for machining different height (OPT).

A.T.C. (OPT)

|

ER collet chuck: Ø0.3~Ø6.35mm.(OPT) |

Standard: Electrove Ø1.0 x 1pc/ Guode Ø1.0mm x 10pc. |

|

Precision chuck: Ø0.1~Ø3mm.(standard) |

Fillter: Standard |